Pricing in deconstruction commodities businesses like meat and dairy is practically inseparable from the product you have left to sell. Lack of data about what pricing managers have left to sell certainly factors into the pricing decisions they make.

There are three factors that are required to integrate product availability into pricing:

• Have a very good understanding of your product availability at any point into the foreseeable future.

• Determine what your target sold position is for each product category for each week you intend to price into.

• Create a structured plan for each of those product categories and weeks to understand how much to modify your pricing based on the difference between target and actual (let’s call this a “modifier matrix” for this discussion).

Let’s unpack each of these factors and discuss how we might deal with them:

Factoring product available to sell in deconstruction products is complex for a host of reasons, including supply variability, product trimming, by-products, demand planning variability, and more. This becomes the first, arguably the most, challenging aspect of pricing. Even the best product availability forecast will have a measurable error rate. However, a well-designed product availability system will reduce this error rate dramatically compared to either no product availability system or a spreadsheet model.

One of the biggest error generators in any product availability system is the demand forecast.

Companies can get mired in guesswork because customers don’t order everything they will buy years in advance and they don’t buy the same thing week after week, making the pricing forecast challenging without a good system. A solid product availability system starts with a demand planning forecast using the best forecasting models available. Further, it will have a simple to use interface that allows for adjustments based on the ever changing information from your sales and demand planning teams. When both of these components are designed correctly and used in conjunction with an accurate supply forecast your sales team understands clearly what they have left to sell. This removes the need for guesswork.

Target sold position is a concept that pricing managers can struggle to build strategy around. Pricing managers almost always factor in product availability, but without a consistent strategy to apply remaining product available vs target sold position the modification of prices based on product left to sell is done in a very inconsistent way. This, combined with the lack of a solid product availability forecast, means pricing managers get inconsistent results. This can cause them to lose sales because they priced higher than the market would bear, or they under priced the sale– losing the value they could have generated. If you want to test this, go ask your pricing manager what percentage of a specific product, like sirloins, they want to have sold three weeks from now. It would be surprising if they were able to tell you an exact number. More often than not the answer will be general, such as “I would like to have a couple loads left” or “I want to have it all sold at a good price”. I would strongly suggest you don’t walk away frustrated with their lack of a structured pricing plan – this is a challenge easily solved with the proper tools (like ours!) for them to make these decisions.

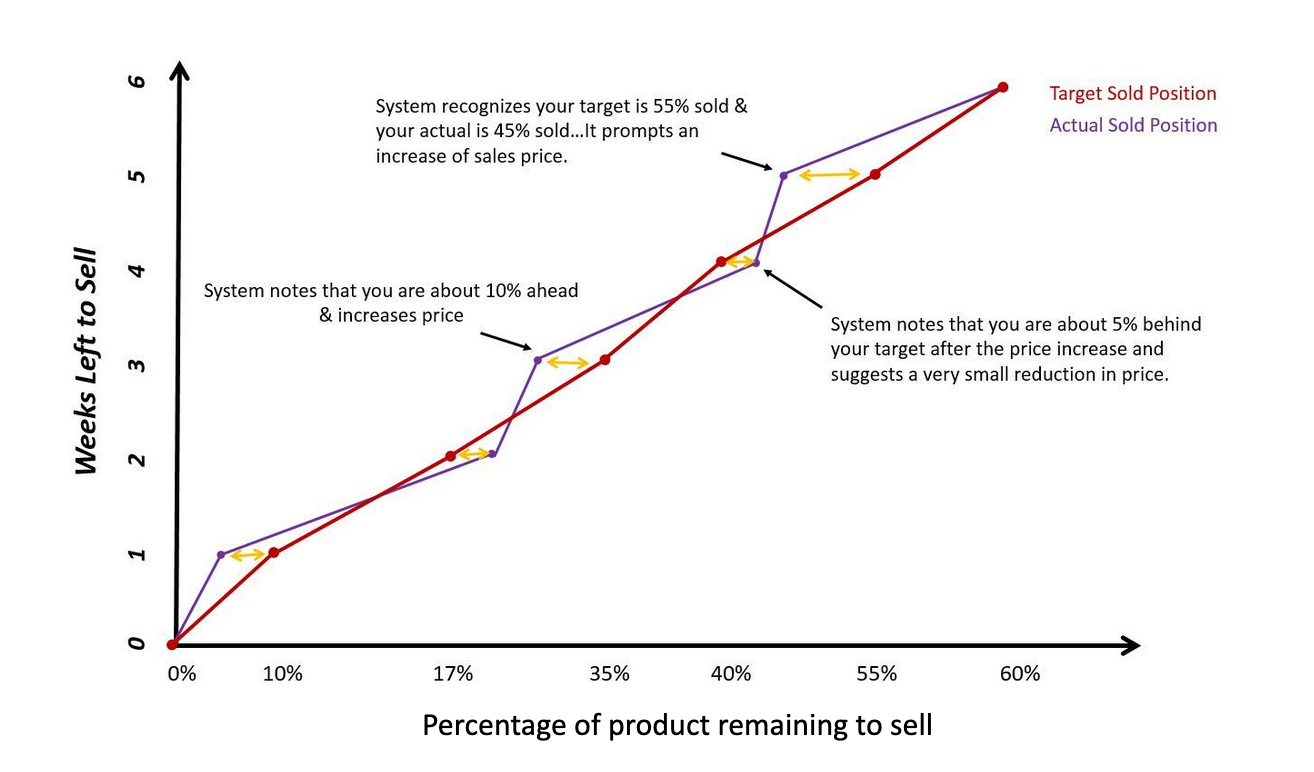

Finally, creating a modifier matrix can be as simple as setting down with your pricing team and talking through how much they would modify pricing for each product category/week based on how much they have left to sell. However, a much better way is to start with price elasticity of demand measurements. Once the price elasticity is calculated, a matrix is created with the product category on one axis and the week in the future on the other. This matrix can then be modified by the users if they deem it necessary. So, for each week in the future you have a price modifier for each product category based on the delta of actual sold position versus target sold position.

By doing this, a price management solution can consistently modify prices for each product code in a uniform way. Of course, there are many steps in creating a price list and we have discussed those in other posts. Once a pricing solution of this type has been implemented you will find that your company is far less often over or under sold.

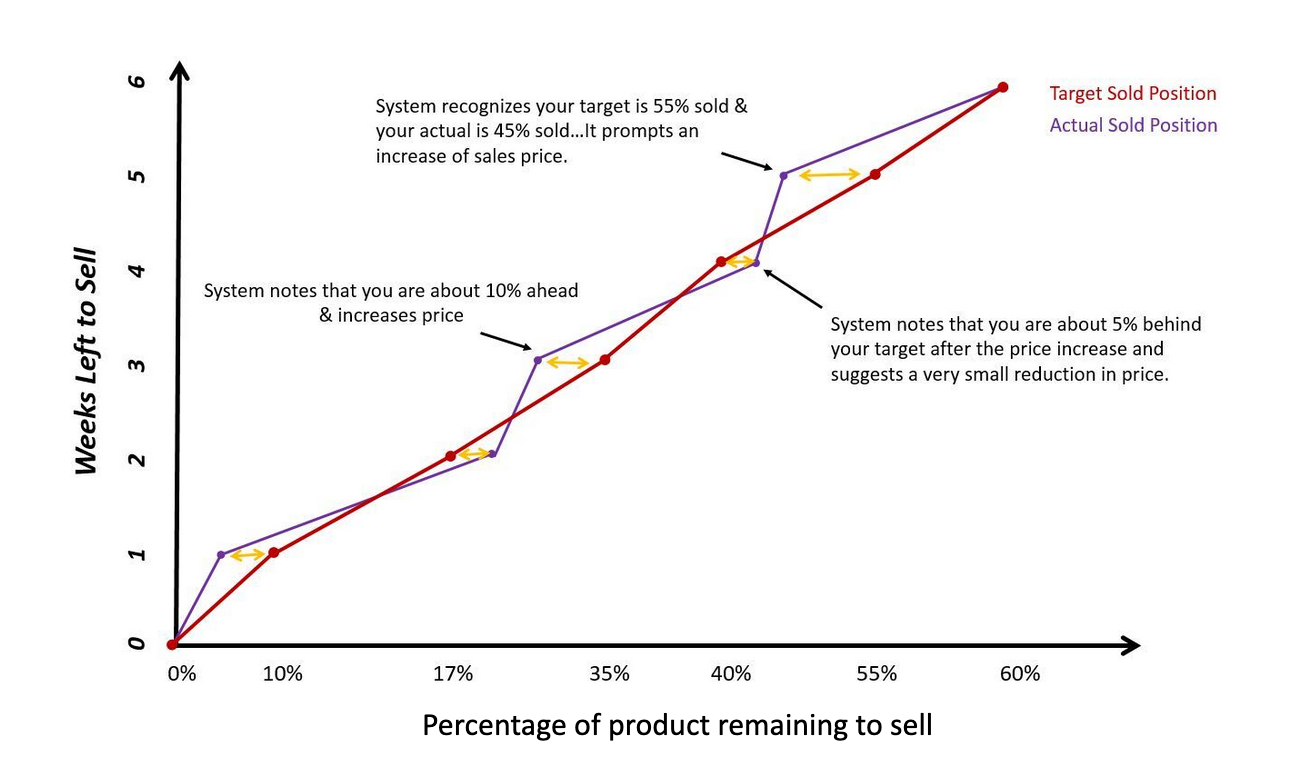

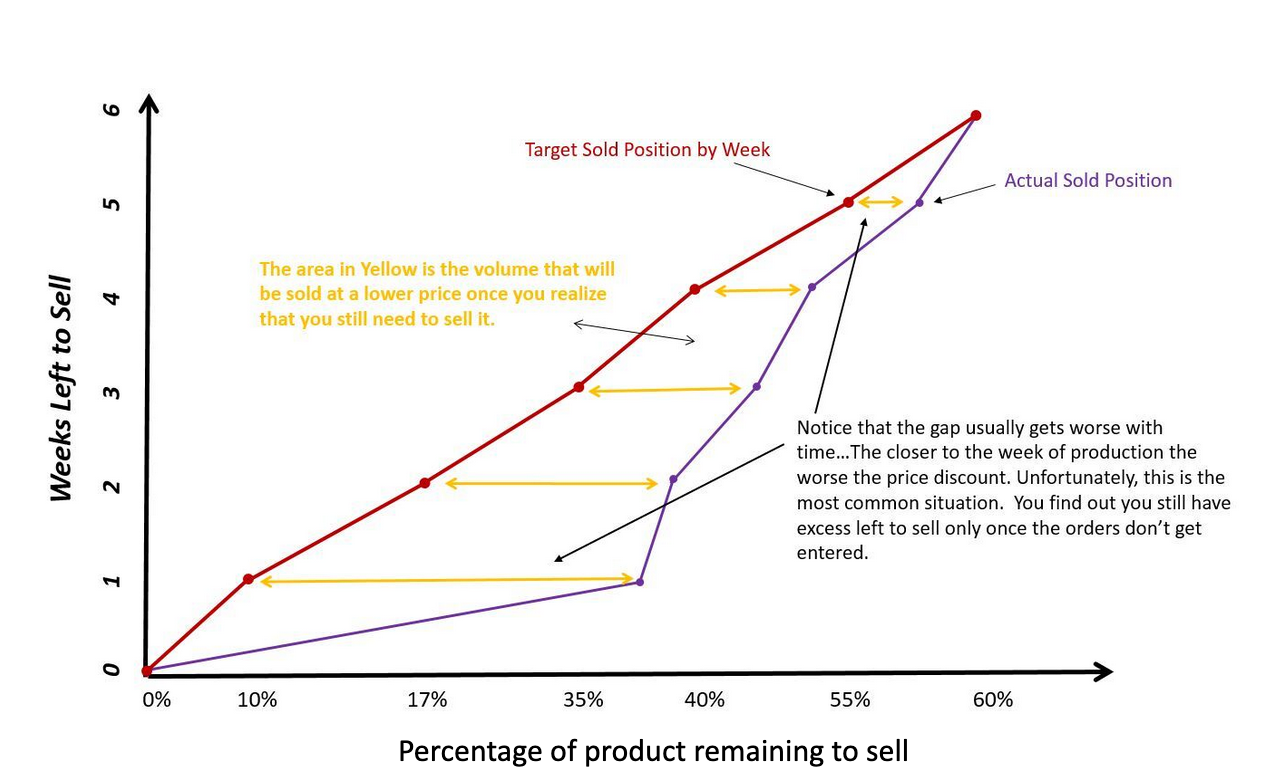

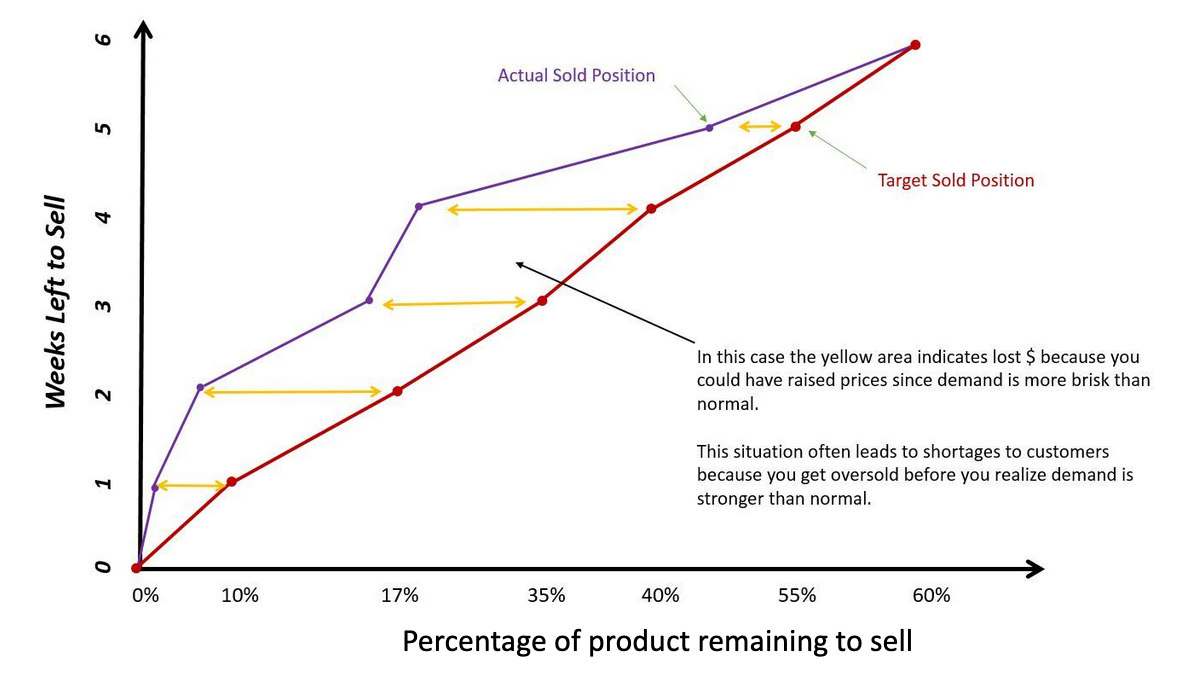

In the three figures below we show what happens when you are oversold, undersold, and finally, what happens when you have a system which integrates pricing and product availability with a target vs actual sold position.

We have seen this work for our clients, and it will work for you too.

Give us a call to find out more.